The Versatile Applications of Aluminium Sheet and Tube

Aluminium Sheet: Lightweight Strength and Endless Possibilities

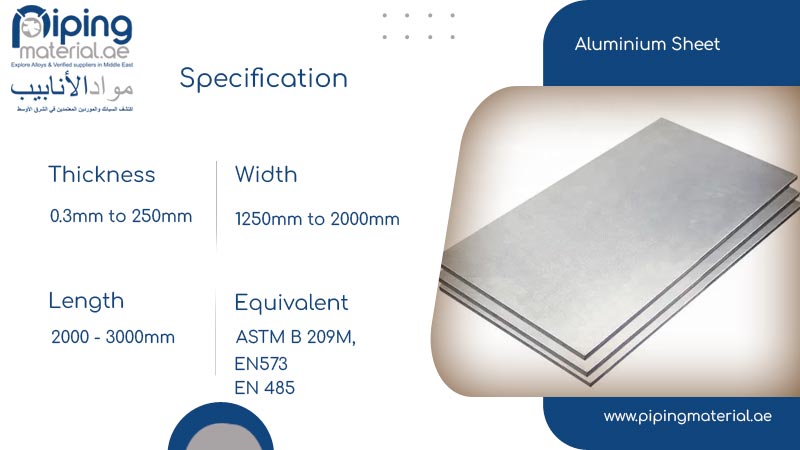

Aluminium sheets are an incredibly versatile material used in various industries, thanks to their unique combination of properties. Composed of pure aluminium or aluminium alloy, these sheets are lightweight, yet remarkably strong. Their exceptional corrosion resistance, malleability, and conductivity make them indispensable in sectors ranging from construction to automotive, aerospace to packaging.

One of the key advantages of aluminium sheet is their remarkable strength-to-weight ratio. This characteristic makes them ideal for applications where weight reduction is crucial without compromising structural integrity. In the aerospace industry, aluminium sheets are widely used in the construction of aircraft wings and fuselage panels, allowing airplanes to be more fuel-efficient and agile. Similarly, in the automotive sector, aluminium sheets contribute to lightweight car bodies, resulting in enhanced fuel economy and improved handling.

The corrosion resistance of aluminium sheets is another critical factor in their widespread use. Unlike many other metals, aluminium naturally forms a thin oxide layer on its surface, protecting it from rust and other forms of corrosion. This inherent property makes aluminium sheets suitable for outdoor applications, such as roofing, siding, and facades. Additionally, this corrosion resistance ensures the longevity of aluminium sheet products, reducing maintenance costs and increasing durability.

The malleability of aluminium sheets enables them to be easily formed into various shapes and sizes. They can be rolled into thin foils or pressed into intricate designs, making them ideal for packaging materials, electrical enclosures, and decorative purposes. Moreover, aluminium sheets can be easily joined through welding, riveting, or adhesive bonding, further expanding their potential applications.

Aluminium Tube: Seamless Solutions for Fluid Conveyance and Structural Support

Aluminium tubes are cylindrical structures made from extruded or drawn aluminium, with a wide range of uses across industries. These tubes exhibit similar properties to aluminium sheets, such as lightweight nature, corrosion resistance, and exceptional strength. With their inherent versatility, aluminium tubes find applications in sectors such as construction, transportation, and manufacturing.

The lightweight nature of aluminium tube makes them an excellent choice for applications that require ease of transportation and handling. In the construction industry, aluminium tubes are used for scaffolding, offering a sturdy and lightweight alternative to traditional steel structures. This makes construction sites safer and more efficient, with easier assembly and disassembly. Additionally, aluminium tubes are extensively used in the manufacture of furniture, sporting goods, and outdoor structures due to their durability and low weight.

The corrosion resistance of aluminium tubes ensures their suitability for fluid conveyance systems. In industries such as plumbing, HVAC (Heating, Ventilation, and Air Conditioning), and automotive, aluminium tubes are commonly used for conveying liquids and gases. Their resistance to corrosion prevents leaks and ensures the longevity of the system, reducing maintenance costs and increasing overall efficiency.

Aluminium tubes also find extensive use in structural applications. They can be shaped, bent, and extruded into various configurations, providing excellent support and stability. The construction of lightweight frames, bicycle frames, and even parts of aircraft structures benefits greatly from the strength and versatility of aluminium tubes.

Furthermore, aluminium tubes have excellent thermal conductivity, making them ideal for applications that require efficient heat transfer. Heat exchangers, radiators, and air conditioning systems often utilize aluminium tubes due to their ability to quickly dissipate heat.

In conclusion, aluminium sheets and tubes offer remarkable advantages and numerous applications across a wide range of industries. Their lightweight nature, combined with exceptional strength, corrosion resistance, and malleability, make them indispensable materials for construction, transportation, manufacturing, and various other sectors. With their versatility and adaptability, aluminium sheets and tubes continue to play a significant role in shaping modern industries and driving innovation forward.

Recent Post

What is The Meaning of a Medusa Tattoo?

January 9, 2025

The Meaning of Encanto in Spanish and Origin

January 4, 2025

Equivalent Phrases For “Including But Not Limited To”

December 30, 2024

How To Make Weekend Greetings More Fun?

December 30, 2024

10 Modern Sayings Similar To “Be There Or Be Square”

December 30, 2024