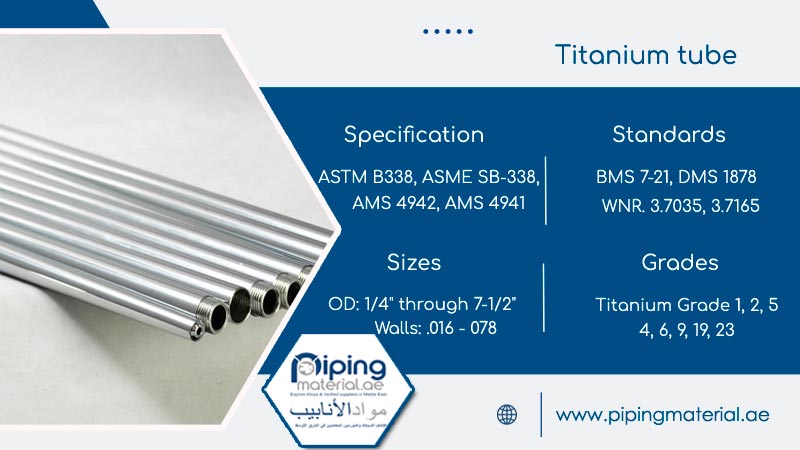

Unraveling the Strength and Versatility of Titanium Pipes and Tubes

Introduction:

In the realm of modern engineering and industry, titanium has emerged as an exceptional material due to its remarkable properties. One of the key applications of titanium lies in the manufacturing of pipes and tubes. With their impressive strength, durability, and corrosion resistance, titanium pipe and tubes have become indispensable in various sectors ranging from aerospace to oil and gas. In this blog post, we will delve into the fascinating world of titanium pipes and tubes, exploring their unique attributes and diverse applications.

Unveiling the Properties of Titanium:

Titanium boasts a myriad of outstanding properties that make it an ideal material for pipe and tube manufacturing. First and foremost, titanium is renowned for its exceptional strength-to-weight ratio. In fact, it surpasses other metals such as steel, copper, and aluminum in this regard. This strength allows titanium pipes and tubes to withstand high pressures and extreme temperatures, making them suitable for applications in challenging environments.

Furthermore, titanium exhibits remarkable resistance to corrosion. It forms a protective oxide layer on its surface, providing a robust barrier against corrosive elements. This corrosion resistance is particularly valuable in industries such as chemical processing, oil and gas, and marine, where exposure to harsh chemicals and saltwater is common. Titanium pipes and tubes ensure long-term reliability and reduced maintenance costs in such demanding environments.

Applications of Titanium Pipes and Tubes:

- Aerospace Industry: Titanium’s lightweight nature, combined with its strength and corrosion resistance, has made it an indispensable material in the aerospace industry. Titanium pipes and tubes are extensively used in aircraft hydraulic systems, fuel lines, and engine components. Their high strength and durability enable them to withstand the rigorous demands of flight conditions, ensuring safety and reliability.

- Oil and Gas Industry: In the oil and gas sector, where corrosive environments and extreme temperatures are prevalent, titanium pipes and tubes provide an optimal solution. They are widely utilized in offshore platforms, subsea equipment, and pipelines for oil and gas transportation. Titanium’s corrosion resistance ensures the integrity of these critical infrastructures, while its ability to withstand high pressures and temperatures contributes to operational efficiency.

- Chemical Processing: Titanium’s resistance to corrosion and chemical attack makes it an ideal choice for the chemical processing industry. Titanium pipes and tubes are employed in chemical reactors, heat exchangers, and piping systems handling corrosive substances. Their longevity and resistance to degradation enable safe and efficient processing of various chemicals, enhancing productivity and minimizing downtime.

- Medical and Healthcare: Titanium’s biocompatibility and non-toxicity have found widespread use in the medical field. Titanium tubes are utilized in the manufacturing of implants, such as hip and knee replacements, due to their excellent compatibility with the human body. Their strength, lightweight nature, and resistance to corrosion make them ideal for biomedical applications, facilitating faster healing and improved patient outcomes.

Conclusion:

Titanium pipes and tubes have emerged as vital components in numerous industries, owing to their exceptional properties and versatility. Their strength, corrosion resistance, and lightweight nature make them indispensable in applications ranging from aerospace and oil and gas to chemical processing and healthcare. As technology continues to advance, the demand for titanium pipes and tubes is expected to grow further, enabling new frontiers of innovation and exploration.

In a world where performance, reliability, and efficiency are paramount, titanium pipes and tubes stand as a testament to the extraordinary capabilities of this remarkable metal. With their inherent strength and resistance to corrosion, they continue to shape industries, pushing the boundaries of what is possible and opening up a world of endless possibilities.

Recent Post

What is The Meaning of a Medusa Tattoo?

January 9, 2025

The Meaning of Encanto in Spanish and Origin

January 4, 2025

Equivalent Phrases For “Including But Not Limited To”

December 30, 2024

How To Make Weekend Greetings More Fun?

December 30, 2024

10 Modern Sayings Similar To “Be There Or Be Square”

December 30, 2024